Since Louis Robert of France invented the first continuous paper machine in 1799, this technology has reshaped the spread of human civilization at an astonishing pace. Over 200 years, paper machines have evolved from primitive hand-cranked prototypes into modern giants with a speed exceeding 1500 meters per minute, driven by a continuous relay of technological innovations.

Germination: From Lab to Mass Production

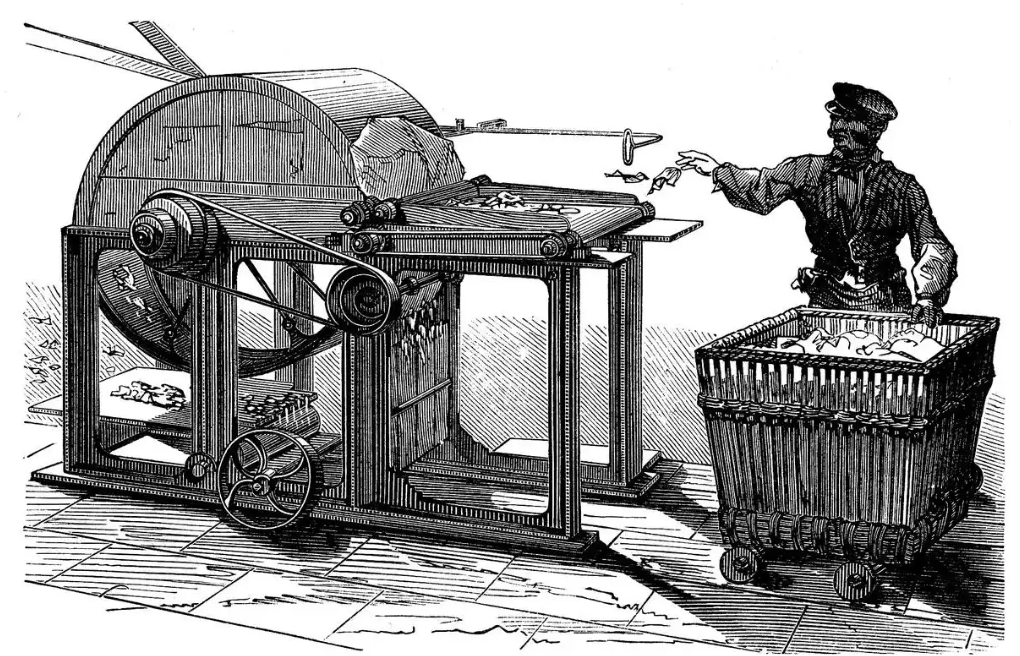

Louis Robert’s invention in 1799 marked the end of manual sheet-by-sheet papermaking. The primitive hand-cranked machine, with a 640mm-wide and 3000mm-long copper wire mesh and a speed of about 5 meters per minute, laid the core logic of continuous papermaking.

In 1803, funded by stationer Henry Fourdrinier, British engineer Bryan Donkin built the first mass-produced Fourdrinier machine and installed it at Frogmore Paper Mill in the UK. With an 813mm paper width and a continuous dewatering press section, it officially kicked off the era of industrial papermaking.

Pioneering: Breakthroughs in Key Technologies

In the first half of the 19th century, core modules of paper machines took shape one after another:

- Cylinder Mould Technology: Invented by Braman in 1805, it laid the foundation for various paper machine types.

- Drying System: Dryers appeared in 1816, initially heated by charcoal without covers; in 1823, Crompton invented steam-heated dryers with dryer felts, greatly boosting drying efficiency.

- Press & Wire Section Optimization: John Dickinson patented the second press in 1817; Thomas Barutt created wire shaking and watermark devices in 1830, improving paper quality and stability.

By 1840, the Fourdrinier machine’s width exceeded 1525mm (60 inches), paving the way for large-scale production.

Leap: Revolution in Power & Automation

From the late 19th to early 20th century, industrial revolution achievements deeply penetrated papermaking:

- Power Innovation: In 1894, an Austrian paper mill first adopted electric motor drive instead of steam engines, enhancing speed and stability.

- High-Speed Exploration: The largest paper machine in the US emerged in 1896, with 4060mm width and 152m/min speed; the invention of vacuum couch rolls in 1908 optimized wire section dewatering.

- Electric Drive Upgrade: In 1909, Voith and Brown Boveri jointly developed sectional electric drive, enabling precise speed synchronization of all machine parts.

In the mid-20th century, hydraulic headboxes and layered headboxes ensured uniform paper formation; variable crown rolls solved roll deflection at high speeds.

Peak: Speed & Limits of Modern Paper Machines

From the late 20th to early 21st century, paper machines entered an era of “speed competition”:

In 1993, Machine 6 at Finland’s Jämsänkoski Mill produced 56g/m² supercalendered paper at 1502m/min with a 10.1m wire width; the same year, Machine 7 at Kaipola Mill set a newsprint record of 1530m/min. These giants made by Valmet represented the global pinnacle of papermaking technology.

Meanwhile, mature twin-wire machines, composite presses and air-cushion headboxes achieved breakthroughs in width, speed and quality; new materials like plastic wires and tungsten carbide dewatering boards improved durability and efficiency.

Retrospect & Prospect

From Robert’s hand-cranked machine to today’s high-speed giants, the history of paper machines is both a technological iteration and a witness to the accelerated spread of human civilization. It revolutionized paper production and enabled the mass popularization of knowledge and information. Now, amid the digital wave, paper machines are evolving towards energy-saving, intelligence and special paper production, continuing their legend in the new era.

Post time: Jan-29-2026