100% Original Toilet Paper Machine Maker - Inclined Wire Toilet Paper Making Machine – Dingchen

100% Original Toilet Paper Machine Maker - Inclined Wire Toilet Paper Making Machine – Dingchen Detail:

| 1.Raw material | Bleached Virgin pulp(NBKP, LBKP); Recycle White Cutting |

| 2.Output paper | Jumbo Roll for Napkin tissue paper,Facial tissue paper and Toilet paper |

| 3. Output paper weight | 13-40g/m2 |

| 4.Capacity | 20-40 Tons per day |

| 5. Net paper width | 2850-3600mm |

| 6. Wire width | 3300-4000mm |

| 7.Working speed | 350-500m/min |

| 8. Designing speed | 600m/min |

| 9. Rail gauge | 3900-4600mm |

| 10. Drive way | Alternating current frequency converter speed control, sectional drive. |

| 11.Layout type | Left or right hand machine. |

Wood pulp and White cuttings →Stock preparation system→Headbox→Wire forming section→Drying section→Reeling section

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 250 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 11workers/shift, 3 shifts/24hours

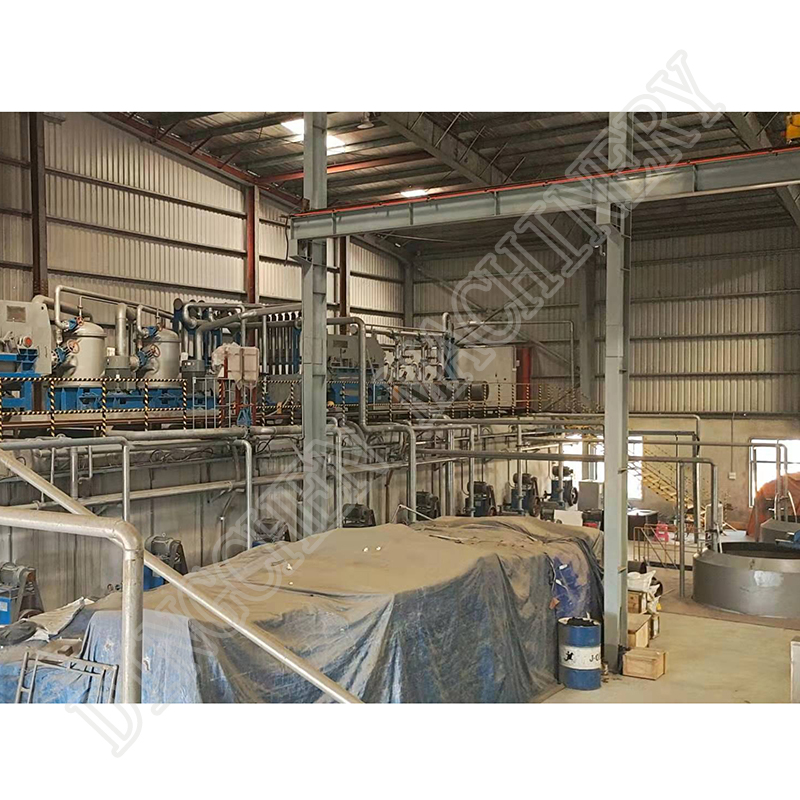

Product detail pictures:

Related Product Guide:

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for 100% Original Toilet Paper Machine Maker - Inclined Wire Toilet Paper Making Machine – Dingchen , The product will supply to all over the world, such as: Surabaya, Plymouth, Vietnam, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We've got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!