2022 New Style Full Automatic Toilet Paper Rewinding Machine - Inclined Wire Toilet Paper Making Machine – Dingchen

2022 New Style Full Automatic Toilet Paper Rewinding Machine - Inclined Wire Toilet Paper Making Machine – Dingchen Detail:

| 1.Raw material | Bleached Virgin pulp(NBKP, LBKP); Recycle White Cutting |

| 2.Output paper | Jumbo Roll for Napkin tissue paper,Facial tissue paper and Toilet paper |

| 3. Output paper weight | 13-40g/m2 |

| 4.Capacity | 20-40 Tons per day |

| 5. Net paper width | 2850-3600mm |

| 6. Wire width | 3300-4000mm |

| 7.Working speed | 350-500m/min |

| 8. Designing speed | 600m/min |

| 9. Rail gauge | 3900-4600mm |

| 10. Drive way | Alternating current frequency converter speed control, sectional drive. |

| 11.Layout type | Left or right hand machine. |

Wood pulp and White cuttings →Stock preparation system→Headbox→Wire forming section→Drying section→Reeling section

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 250 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 11workers/shift, 3 shifts/24hours

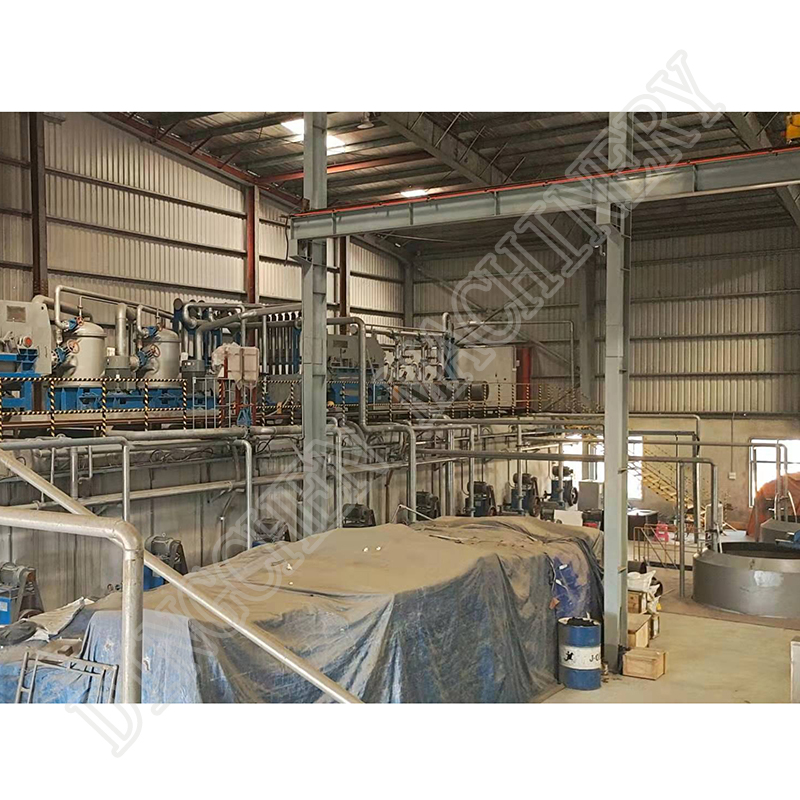

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for 2022 New Style Full Automatic Toilet Paper Rewinding Machine - Inclined Wire Toilet Paper Making Machine – Dingchen , The product will supply to all over the world, such as: Victoria, luzern, Grenada, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!