2022 New Style Full Automatic Toilet Paper Rewinding Machine - Toilet Paper Machine Cylinder Mould Type – Dingchen

2022 New Style Full Automatic Toilet Paper Rewinding Machine - Toilet Paper Machine Cylinder Mould Type – Dingchen Detail:

| 1.Raw material | Waste books paper |

| 2.Output paper | Toilet paper;Tissue paper |

| 3.Output paper weight | 15-30 g/m2 |

| 4.Output paper width | 1200-3200mm |

| 5.Wire width | 1450-3650 mm |

| 6.Capacity | 2-15 Tons Per Day |

| 7. Working speed | 50-180m/min |

| 8. Design speed | 80-210m/min |

| 9.Rail gauge | 1800-4300 mm |

| 10.Drive way | Alternating current frequency conversion adjustable speed, sectional drive |

| 11.Layout | Left or right hand machine |

Waste books paper →Stock preparation system→Cylinder mould part→Dryer part→Reeling part

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 250 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 7 workers/shift, 3 shifts/24hours

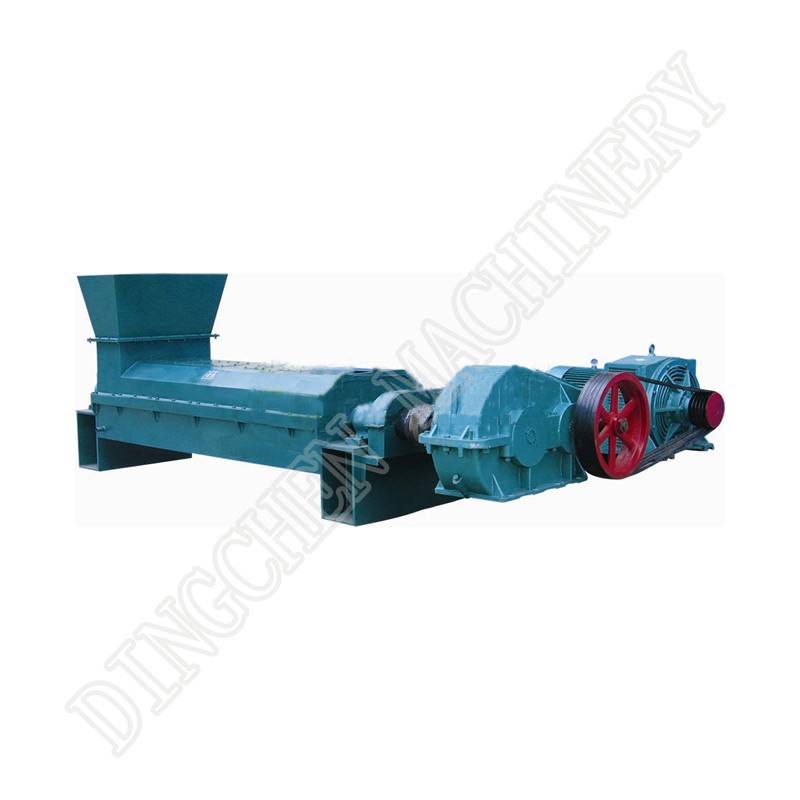

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for 2022 New Style Full Automatic Toilet Paper Rewinding Machine - Toilet Paper Machine Cylinder Mould Type – Dingchen , The product will supply to all over the world, such as: Zambia, Montreal, Danish, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!