Discountable price Toilet Paper Production Line - Inclined Wire Toilet Paper Making Machine – Dingchen

Discountable price Toilet Paper Production Line - Inclined Wire Toilet Paper Making Machine – Dingchen Detail:

| 1.Raw material | Bleached Virgin pulp(NBKP, LBKP); Recycle White Cutting |

| 2.Output paper | Jumbo Roll for Napkin tissue paper,Facial tissue paper and Toilet paper |

| 3. Output paper weight | 13-40g/m2 |

| 4.Capacity | 20-40 Tons per day |

| 5. Net paper width | 2850-3600mm |

| 6. Wire width | 3300-4000mm |

| 7.Working speed | 350-500m/min |

| 8. Designing speed | 600m/min |

| 9. Rail gauge | 3900-4600mm |

| 10. Drive way | Alternating current frequency converter speed control, sectional drive. |

| 11.Layout type | Left or right hand machine. |

Wood pulp and White cuttings →Stock preparation system→Headbox→Wire forming section→Drying section→Reeling section

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 250 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 11workers/shift, 3 shifts/24hours

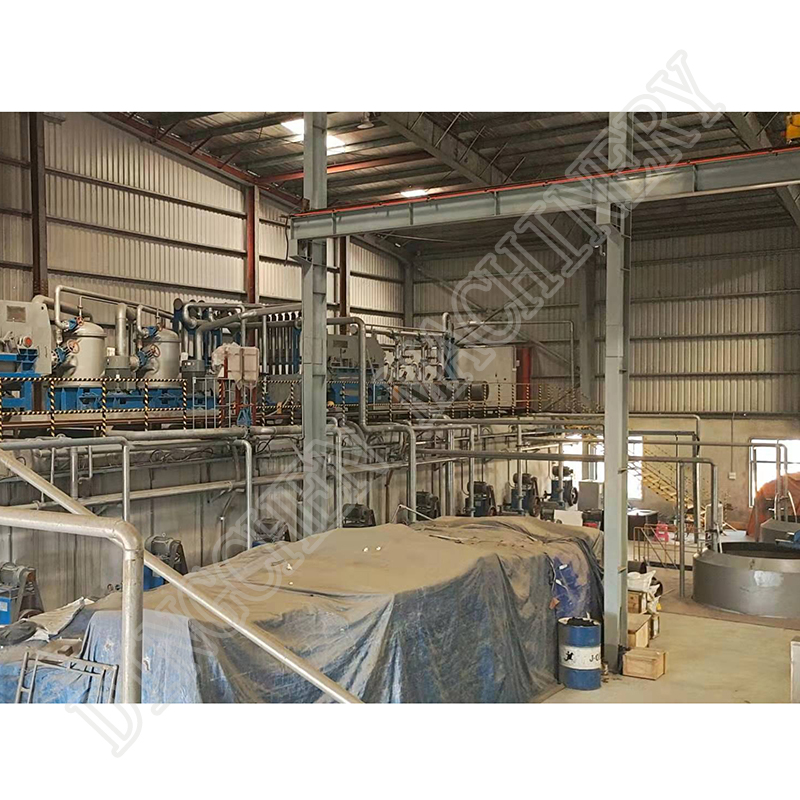

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Discountable price Toilet Paper Production Line - Inclined Wire Toilet Paper Making Machine – Dingchen , The product will supply to all over the world, such as: America, Malawi, Bangladesh, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!