OEM Customized Toilet Tissue Making Machine - Inclined Wire Toilet Paper Making Machine – Dingchen

OEM Customized Toilet Tissue Making Machine - Inclined Wire Toilet Paper Making Machine – Dingchen Detail:

| 1.Raw material | Bleached Virgin pulp(NBKP, LBKP); Recycle White Cutting |

| 2.Output paper | Jumbo Roll for Napkin tissue paper,Facial tissue paper and Toilet paper |

| 3. Output paper weight | 13-40g/m2 |

| 4.Capacity | 20-40 Tons per day |

| 5. Net paper width | 2850-3600mm |

| 6. Wire width | 3300-4000mm |

| 7.Working speed | 350-500m/min |

| 8. Designing speed | 600m/min |

| 9. Rail gauge | 3900-4600mm |

| 10. Drive way | Alternating current frequency converter speed control, sectional drive. |

| 11.Layout type | Left or right hand machine. |

Wood pulp and White cuttings →Stock preparation system→Headbox→Wire forming section→Drying section→Reeling section

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 250 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 11workers/shift, 3 shifts/24hours

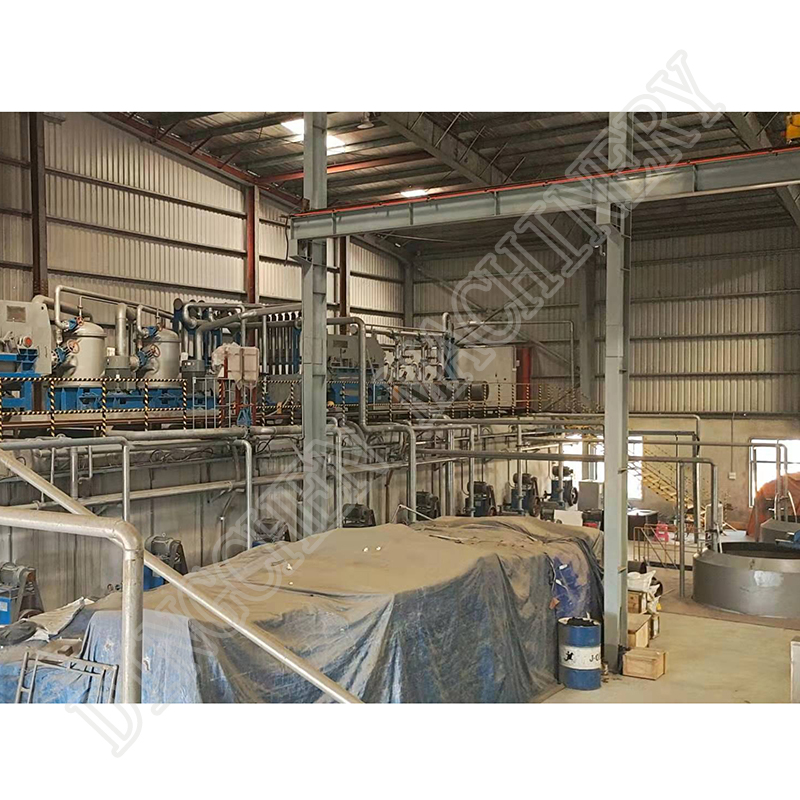

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for OEM Customized Toilet Tissue Making Machine - Inclined Wire Toilet Paper Making Machine – Dingchen , The product will supply to all over the world, such as: Portugal, European, Mozambique, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.