Reasonable price Best Price Kraft Paper Making Machine - Fluting&Testliner Paper Production Line Cylinder Mould Type – Dingchen

Reasonable price Best Price Kraft Paper Making Machine - Fluting&Testliner Paper Production Line Cylinder Mould Type – Dingchen Detail:

| 1.Raw material | Old Carton,OCC |

| 2.Output paper | Testliner paper,Kraftliner paper,Fluting paper,Kraft paper,Corrugated paper |

| 3.Output paper weight | 80-300 g/m2 |

| 4.Output paper width | 1800-5100mm |

| 5.Wire width | 2300-5600 mm |

| 6.Capacity | 20-200 Tons Per Day |

| 7. Working speed | 50-180m/min |

| 8. Design speed | 80-210m/min |

| 9.Rail gauge | 2800-6200 mm |

| 10.Drive way | Alternating current frequency conversion adjustable speed, sectional drive |

| 11.Layout | Left or right hand machine |

Old cartons →Stock preparation system→Cylinder mould part→Press part→Dryer group→Sizing press part→Re-dryer group→Calendering part →Reeling part→Slitting&Rewinding part

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

(1)The seller will provide technical support and send engineers for installation, test run the whole paper production line and training the buyer’s workers

(2)As different paper production line with different capacity, it will take different time to install and test run the paper production line. As usual, for regular paper production line with 50-100t/d, it will take about 4-5months,but mainly depend on the local factory and workers’ cooperation situation.

(3)The buyer shall be responsible for the salary, visa, round trip tickets, train tickets, accommodation and quarantine charges for the engineers

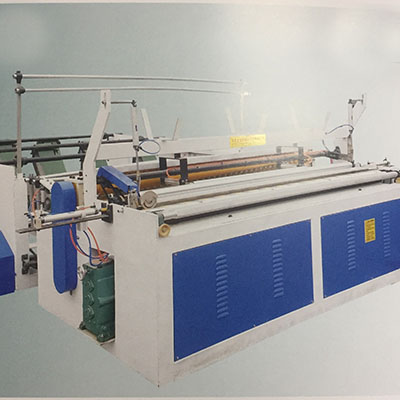

Product detail pictures:

Related Product Guide:

Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of Reasonable price Best Price Kraft Paper Making Machine - Fluting&Testliner Paper Production Line Cylinder Mould Type – Dingchen , The product will supply to all over the world, such as: Greece, Jamaica, Myanmar, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!