Special Price for Manufacturer Toilet Paper Rewinding Machine - Inclined Wire Toilet Paper Making Machine – Dingchen

Special Price for Manufacturer Toilet Paper Rewinding Machine - Inclined Wire Toilet Paper Making Machine – Dingchen Detail:

| 1.Raw material | Bleached Virgin pulp(NBKP, LBKP); Recycle White Cutting |

| 2.Output paper | Jumbo Roll for Napkin tissue paper,Facial tissue paper and Toilet paper |

| 3. Output paper weight | 13-40g/m2 |

| 4.Capacity | 20-40 Tons per day |

| 5. Net paper width | 2850-3600mm |

| 6. Wire width | 3300-4000mm |

| 7.Working speed | 350-500m/min |

| 8. Designing speed | 600m/min |

| 9. Rail gauge | 3900-4600mm |

| 10. Drive way | Alternating current frequency converter speed control, sectional drive. |

| 11.Layout type | Left or right hand machine. |

Wood pulp and White cuttings →Stock preparation system→Headbox→Wire forming section→Drying section→Reeling section

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 250 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 11workers/shift, 3 shifts/24hours

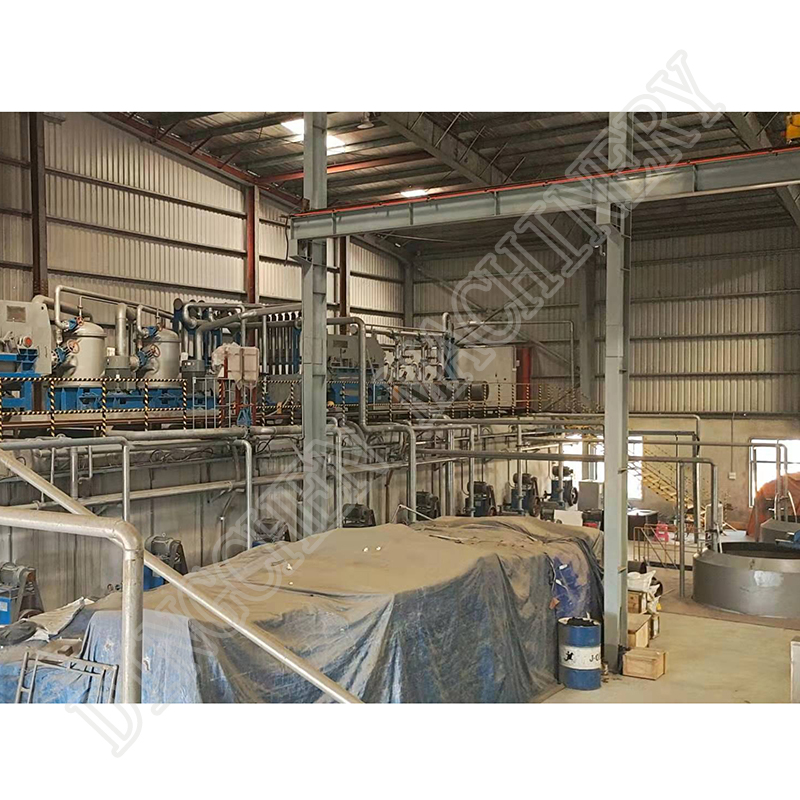

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Special Price for Manufacturer Toilet Paper Rewinding Machine - Inclined Wire Toilet Paper Making Machine – Dingchen , The product will supply to all over the world, such as: UAE, Greenland, Monaco, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!