A4 Printing Paper Machine Fourdrinier Type Office Copy Paper Making Plant

Main Technical Parameter

| 1.Raw material | Waste white paper & Virgin pulp |

| 2.Output paper | A4 Printing paper,Copy paper,Office paper |

| 3.Output paper weight | 70-90 g/m2 |

| 4.Output paper width | 1700-5100mm |

| 5.Wire width | 2300-5700 mm |

| 6.Headbox lip width | 2150-5550mm |

| 7.Capacity | 10-200 Tons Per Day |

| 8. Working speed | 60-400m/min |

| 9. Design speed | 100-450m/min |

| 10.Rail gauge | 2800-6300 mm |

| 11.Drive way | Alternating current frequency conversion adjustable speed, sectional drive |

| 12.Layout | Single layer,Left or right hand machine |

Process Technical Condition

Virgin pulp&White scrap paper → Stock preparation system→Wire part→Press part→Dryer group→Sizing press part→ Re-dryer group→Calendering part →Paper scanner→Reeling part→Slitting&Rewinding part

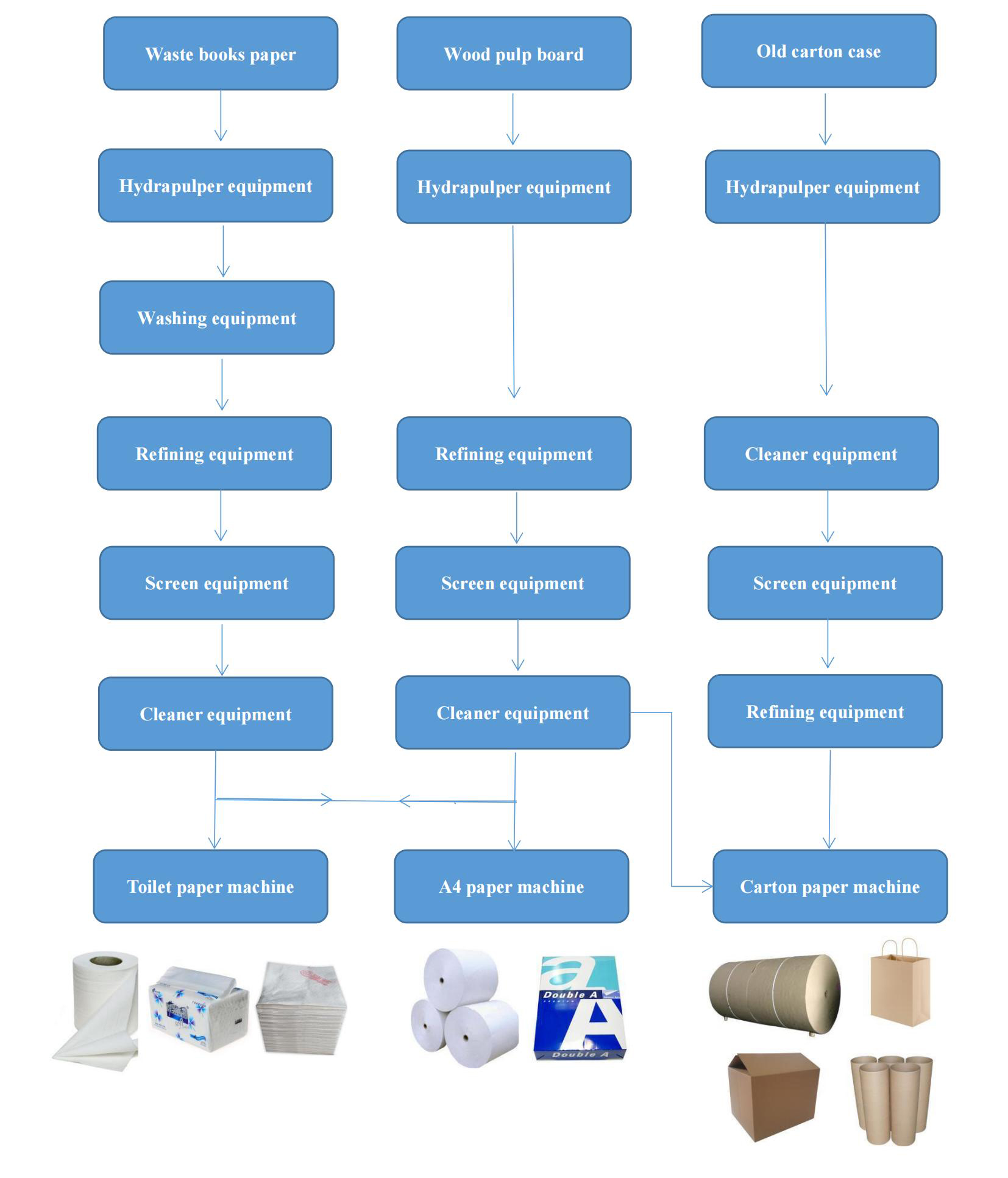

Paper making flowchart(waste paper or wood pulp board as raw material)

Process Technical Condition

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

Feasibility Study

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 300 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 11workers/shift, 3 shifts/24hours

Warranty

(1) The warranty period for the main equipment is 12 months after successful test-run, including cylinder mold, head box, dryer cylinders, various rollers, wire table, frame, bearing, motors, frequency conversion controlling cabinet, electrical operation cabinet etc., but doesn’t include the matched wire, felt, doctor blade, refiner plate and other quick wearing parts.

(2) Within the warranty, the seller will change or maintain the broken parts for free (except for the damage by human error and the quick-wear parts)