OEM China Kraft Paper Mill Project Cost - Multi-wire Kraftliner&Duplex Paper Mill Machinery – Dingchen

OEM China Kraft Paper Mill Project Cost - Multi-wire Kraftliner&Duplex Paper Mill Machinery – Dingchen Detail:

| 1.Raw material | Waste paper,Cellulose |

| 2.Output paper | White top Duplex paper,Kraftliner paper |

| 3.Output paper weight | 100-250 g/m2 |

| 4.Output paper width | 2880-5100mm |

| 5.Wire width | 3450-5700 mm |

| 6.Capacity | 60-500 Tons Per Day |

| 7. Working speed | 100-450m/min |

| 8. Design speed | 150-500m/min |

| 9.Rail gauge | 4000-6300 mm |

| 10.Drive way | Alternating current frequency conversion adjustable speed, sectional drive |

| 11.Layout | Left or right hand machine |

Waste paper and Cellulose →Double Stock preparation system→Multi-Wire part→Press part→Dryer group→Sizing press part→Re-dryer group→Calendering part →Paper scanner→Reeling part→Slitting&Rewinding part

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 300 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 12workers/shift, 3 shifts/24hours

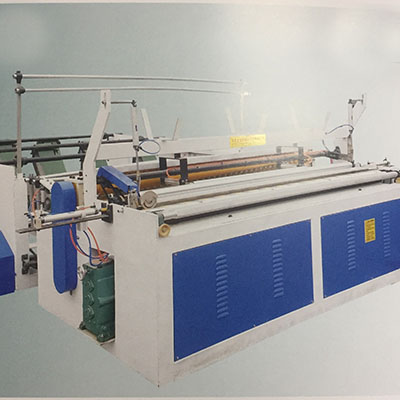

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for OEM China Kraft Paper Mill Project Cost - Multi-wire Kraftliner&Duplex Paper Mill Machinery – Dingchen , The product will supply to all over the world, such as: Netherlands, Philadelphia, Amman, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!